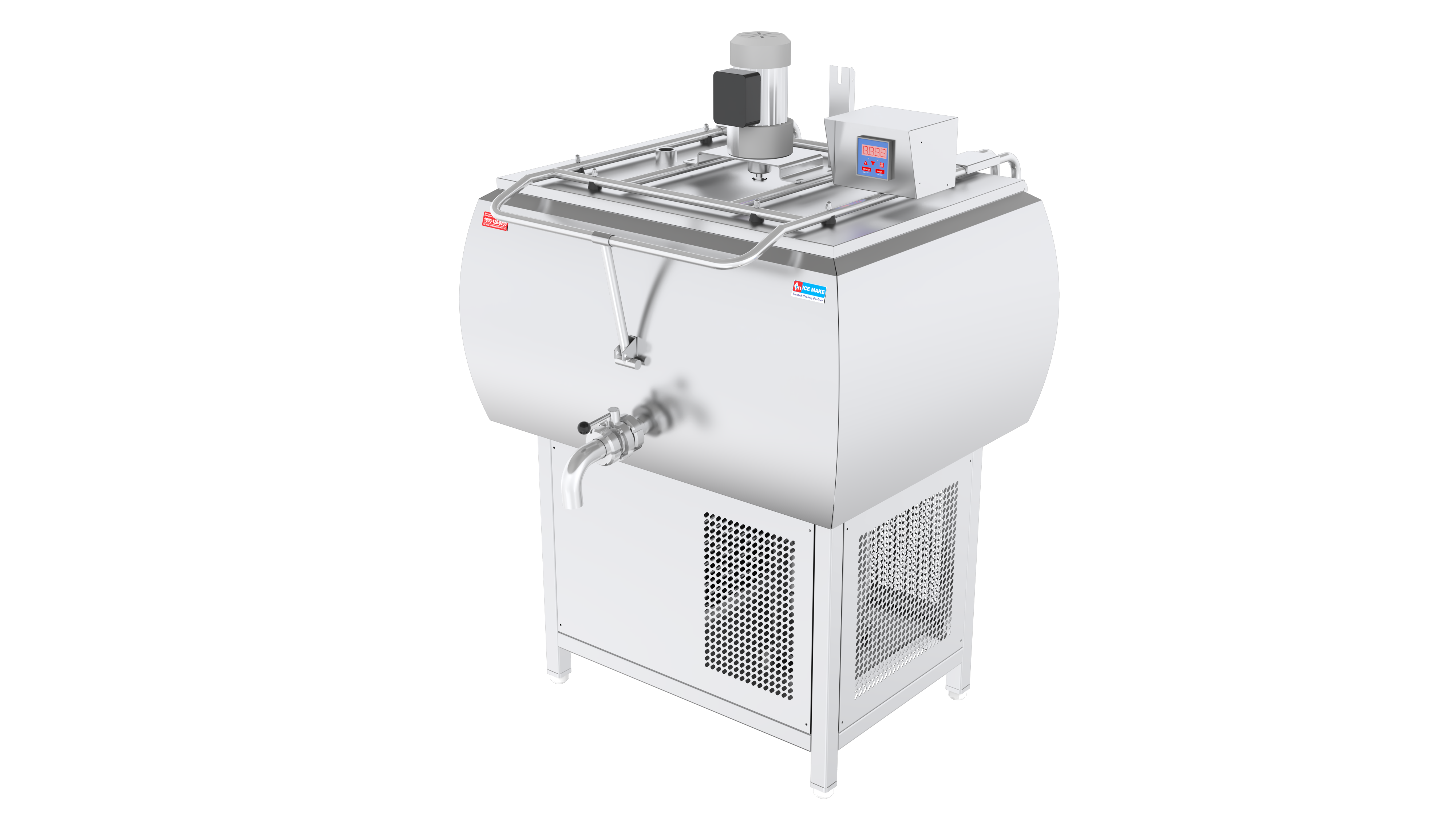

Milk Cooler

Price 62000 INR/ Unit

MOQ : 1 Unit

Milk Cooler Specification

- Product Type

- Milk Cooler

- General Use

- Dairy Industry, Milk Storage

- Material

- Stainless Steel

- Capacity

- 500 Liters Ltr

- Weight (kg)

- 240 Kilograms (kg)

- Computerized

- No

- Control System

- Digital Control Panel

- Cooling Mode

- Direct Expansion

- Sterilization Method

- Hot Water/Steam

- Motor Power

- 1.5 kW Watt (W)

- Dimension (L*W*H)

- 1650 x 1100 x 1280 mm Millimeter (mm)

- Feature

- Energy Efficient, Corrosion Resistant

- Color

- Silver

Milk Cooler Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About Milk Cooler

Growing with the developments in the industry, we are duly manufacturing and exporting an advanced range of Milk Cooler (Can). Extensively supplied to many dairy industries, these coolers are widely used to cool the processed milk after boiling at a required temperature. Our highly skilled workforce uses only certified quality of food grade materials for the construction and engineering of the coolers. In confirmation with the industry standards, the Milk Cooler is installed in the milk distribution systems for preserving the quality and purity.

Key Features

- These coolers are available in two options, with close and open type coil

- Our wide range of coolers for milk storage is available in different capacities

- Excellent storage of milk even in the case of power failure

Specifications:

| Close Type Coil | Open Type Coil | ||||

| 1 | Get Heat Transfer area 20% due to coil close | 1 | Get Heat Transfer Area 100% due to Coil Open | ||

| 2 | High Power Consumption | 2 | Low Power Consumption hence save money on electricity bills | ||

| 3 | Easy To clean | 3 | Difficult to clean | ||

| 4 | Fast Temperature loss | 4 | Slow temperature loss hence increased efficiency | ||

- Temperature : 2oC

- Application for : Loose Milk Storage

- Capacity : 2, 4, 6, 8, 10, 12 Can 40 Ltr - 2, 4, 6, 8, 10, 12, 14, 16, 18 Can 30 Ltr

- Very Best Milk Storage Unit in the Rural India

- Just Run Our Water Cooler Unit for 4 hours and then if Power Goeas off, You can store Milk upto 8 More hours due to water inside the Cooler Tank which keeps Milk cool for long time.

- Even there is big problem of electricity and frequent power cuts, customer / User place ICE around Milk Canss stored in Milk Cooler. Due to the High Density PUF and advance technology, customer can store milk longer.

- Designed to suit local conditions made tough compared to other local & imported / Standard manufacturers.

- All appliances can be made as per clients specification on demand.

- Our appliances are tested for well balance system design, energy, efficient, long lasting performance and maintenance free.

Special Feature

Precision Chilling for Quality Milk

Maintain optimal milk freshness with our Bulk Milk Cooler, designed to rapidly chill and preserve milk using direct expansion technology. This cooler sustains temperatures between 4C and 6C, minimizing spoilage and ensuring safe storage for dairy businesses. The robust stainless steel structure and efficient insulation work together to keep milk at ideal quality levels, even during temporary storage.

Reliable and Durable Construction

Built with food-grade stainless steel and polyurethane foam insulation, this milk cooler prioritizes both hygiene and durability. The stainless steel paddle agitator ensures consistent cooling, while the corrosion-resistant materials extend service life, even in demanding dairy environments. The digital control panel streamlines monitoring, making daily operation straightforward for staff.

Efficient Operation for Dairy Facilities

The Bulk Milk Cooler is leg-mounted for stability and easy installation in dairy plants or cooperative societies. As an energy-efficient and computerized-free solution, it enables reliable milk chilling with a powerful 1.5 kW motor. Standard fittings assure compatibility with diverse dairy setups, while the hot water/steam sterilization feature eases routine cleaning and maintenance.

FAQs of Milk Cooler:

Q: How does the Bulk Milk Cooler maintain milk freshness?

A: The Bulk Milk Cooler utilizes a direct expansion cooling mode, keeping milk consistently between 4C and 6C. Its digital control panel, efficient polyurethane foam insulation, and robust stainless steel design help preserve milk quality by preventing bacterial growth and spoilage during chilling and temporary storage.Q: What is the process for sterilizing the milk cooler?

A: Sterilization is effective and straightforward, as the Bulk Milk Cooler supports hot water or steam sterilization. This method ensures comprehensive cleaning of all contact surfaces, maintaining hygiene in line with dairy industry standards.Q: Where is this milk cooler typically used?

A: This cooler is suited for dairy farms, milk collection centers, and processing plants across India. Its design accommodates bulk milk storage and chilling requirements, making it valuable for distributors, exporters, manufacturers, service providers, and suppliers in the dairy sector.Q: When should the milk be transferred into the cooler?

A: Milk should be transferred into the Bulk Milk Cooler immediately after milking or collection, while it is fresh and at ambient temperature. Rapid chilling is crucial to preserve the milks quality and extend its shelf life.Q: What are the main benefits of using this milk cooler?

A: Key benefits include energy efficiency, corrosion resistance, easy operation with a digital control panel, and robust construction. It also assures excellent milk hygiene, reliable temperature control, and compatibility with standard dairy equipment.Q: How is the temperature of the milk monitored and controlled?

A: The cooler is equipped with a state-of-the-art digital control panel that allows operators to monitor and adjust the temperature settings, ensuring the milk stays precisely within the optimal range for safe storage.Q: What materials are used for the milk contact parts, and why?

A: All milk-contact surfaces, including the evaporator and inner tank, are made from high-grade stainless steel (SS 304), known for its corrosion resistance, durability, and ability to maintain sanitary conditions crucial for dairy applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free