Panel Built Modular Isolation Room

Price 100000 INR/ Unit

MOQ : 1 Unit

Panel Built Modular Isolation Room Specification

- Life Span

- 20 years

- Wall Materials

- Insulated sandwich panels (PU or EPS core)

- Door Material

- Powder-coated metal door with sealing gasket

- Dimension (L*W*H)

- Customized, common size: 3000mm*2400mm*2450mm

- Open Style

- Sliding or Hinged

- Connection

- Bolt connection, easy installation

- Insulation

- PU/EPS insulated wall and roof panels

- Window Material

- Clear tempered safety glass

- Material

- Galvanized Steel, PU/EPS sandwich panels

- Roof Material

- Powder-coated steel panel with insulation

- Thickness Of Wall Panel

- 50mm or 75mm (customizable)

- Door

- Single/Double Door

- Window

- 12 windows per room (customizable)

- Window Style

- Fixed or Sliding

- Floor Material

- Epoxy-coated steel plate

- Floor Load

- 200 kg/m

- Roof Dead Load

- 60 kg/m

- Roof Live Load

- 60 kg/m

- Earthquake Intensity

- Up to 8 degree

- Color

- Light Grey, White or Customized

- Use

- Medical isolation, patient quarantine, infection control, cleanroom applications

Panel Built Modular Isolation Room Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2 Week

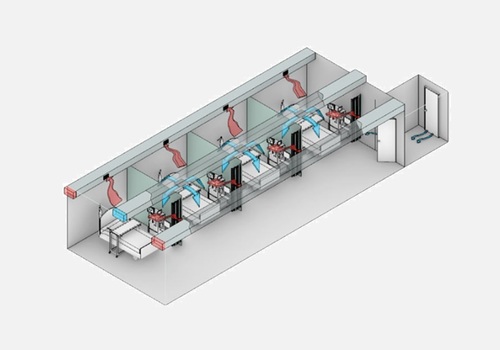

About Panel Built Modular Isolation Room

Ice Make offers panel built isolation rooms that works under negative pressure to avoid any airborne spread of virus or any contamination.

Our objective is to help our nation to meet the challenges of treating corona affected patients and save their lives. Our nation's hospitals and health care sector may need many isolation chamber. The Panel Built isolation chambers can meet demand in very cost effective and within very short time of span, these panels are used to eliminate the spread of COVID-19 by creating instant negative pressure isolation anterooms and airborne infection isolation rooms (AIIR).

India stands at crucial juncture of the curve where next level preparedness is essential to handle Covid-19 affected patients, our modular isolation rooms are design for healthcare facilities throughout the country, helping to protect more healthcare workers and patients and reduce the spread of COVID-19.

Superior Infection Control

Our modular isolation room provides exceptional protection with HEPA-filtered ventilation, antibacterial PVC finishes, and the ability to maintain positive or negative air pressure. This ensures a safe environment for patients and staff while effectively limiting the spread of airborne contaminants.

Rapid and Customizable Assembly

Designed with user convenience in mind, the room is delivered as a prefabricated kit that can be installed within 12 days using bolt connections. Available in multiple sizes and configurations, it allows for customization to meet specific medical or space requirements, ensuring adaptability for various environments.

Built for Safety and Durability

Constructed from galvanized steel and insulated sandwich panels (PU or EPS core), the isolation room boasts Class B1 fire resistance, UV protection, earthquake resistance up to 8 degrees, and a minimum lifespan of 20 years. Its robust finish and easy-clean features make it ideal for demanding healthcare settings.

FAQs of Panel Built Modular Isolation Room:

Q: How is the Panel Built Modular Isolation Room installed on-site?

A: The modular isolation room is delivered as prefabricated panels and assembled using bolt connections, which makes installation straightforward and efficient. Typically, the entire room can be assembled by a trained team within 12 days, minimizing disruption to your facility.Q: What safety and compliance standards does this isolation room meet?

A: This isolation room fully complies with ISO 14644 and GMP standards required for cleanrooms and medical facilities. It also offers fire resistance up to Class B1 and features such as sound insulation and antibacterial surfaces to enhance patient and staff safety.Q: Can the isolation room be customized for different applications or sites?

A: Yes, the modular isolation room can be customized in terms of size, color, number and type of doors/windows, service ports, flooring materials, and humidity control. It is suitable for both indoor and outdoor installations and can be tailored to various medical or cleanroom uses.Q: What type of ventilation and air quality controls are included?

A: The room comes equipped with a HEPA-filtered ventilation system capable of maintaining either positive or negative pressure, which is critical for infection control. Optional humidity control can also be integrated upon request to support specialized cleanroom applications.Q: Where can these modular isolation rooms be used?

A: These rooms are ideal for use in hospitals, quarantine centers, laboratories, and factory cleanrooms, whether indoors or outdoors. They are designed to be relocatable, offering flexibility for temporary or long-term deployment.Q: What benefits does the antibacterial PVC wall finish provide?

A: The antibacterial PVC wall finish offers a smooth, non-porous surface that is easy to clean and disinfect. This reduces the risk of contamination and ensures ongoing compliance with hygiene protocols essential in medical and cleanroom environments.Q: How durable is the modular isolation room and what is its life expectancy?

A: Constructed from galvanized steel and well-insulated sandwich panels, the room can withstand harsh conditionsincluding temperatures from -20C to +50C, UV exposure, and seismic activity up to 8 degrees. The minimum expected lifespan is 20 years, ensuring long-term use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS