Cold Room Panel

Price 1000000 INR/ Unit

Cold Room Panel Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Product Type

- Cold Room Panel

- Weight

- 200 Kilograms (kg)

- Temperature

- -25 Degree C Celsius (oC)

- Color

- Silver

- Power

- 230 Volt (v)

- Voltage

- 220-440 Volt (v)

Cold Room Panel Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Cold Room Panel

Owing to our years of industry experience we have carved out an outstanding position in the market by providing our clients a wide range Cold Room Panel Designed using most modern technology and finest quality raw material this panel is widely used in cold store ceiling temporary housedormitories warehouse workshop and other places for cooling applications Our clients can avail this Cold Room Panel from us in different specifications at industry leading rates

Features

Durable finish standards

Optimum performance

Smooth operation

Longer working life

Technical specification of puf panel

Parameters

Description

Average PUF Density

40 2 Kg m3

PUF Blowing Agent

141B CFC free

Insulation Material

Polyurethane Foam

Temperature range

90oC to 60oC

Penal Type

Discontinuous type with camlock

MOC Of Camlocks

Camlocks body material HIPS and male latch is made of nylon glass field with GI sheet reinforcement Camlock panel joints that are easy to assemble and leakage resistant paneltopanel joints

Type Of Panel Joints

Tongue Groove Joint with Cam lock and all side rubber gaskets

Corner Panel Available

12 x 12 x 162 Maximum Length

Length of wall ceiling panel

2032 mm to 12000 mm 80 to 4725 inch

Ceiling Suspension items with specs

MS bolt with thermal breaking cap 4 mm thickness X 80 X 80 mm AluminiumMS washer plate for load distribution Anchor bolt MS hanging bolt with 40 mm washer 20 mm thickness Sealing to panel MS road Clamp with an insulated crown

Closed cell content

90 to 95

Vapour Permeability

55mgPASM

Water Absorption

Less than 2

Fire Resistance

FR Grade Fire Resistance Grade

Compressive Strength at 10 Deformation

021 Nsqmm For PUF only

Tensile Strength

058 Nsqmm For PUF only

Adhesive StrengthFoam to Sheet

29kgsqmtr

Adhesive Strength Foam to Sheet

29 kgsqmtr

Panel Facing Availability

With Rib or plain on Demand Ribs are provided for more strength

Wall Celling Panel Facing material

PrePainted Galvanised sheet Thickness 045mm

Plain Galvanised sheet Thickness 045mm

SS sheet Grade 316 050mm finish 2B06mm mate No4

SS sheet Grade 304 050mm finish 2B06mm mate No4

Floor Panel Facing Material

PUF Panel with both side tarfelt sheet

PUF Panel with both side 045mm GIPP sheet

PUF Panel with outside GIPP sheet inside 9 mm thick marine ply with 2 mm thick Aluminium Chequered Plate

Specification for Colour Coating

A RAL No 90029003 or its nearest

B Indian Standard code Colour Coating IS 14246 Galvanizing IS 277 Base Metal IS 513

C Organic Coating Type RMP Polyester

D Zinc Coating 120 GSM

E Top Primer Thickness in micron 5 1

F Top Coat Thickness in micron 20 1

G Back Primer Thickness in micron 4 1

H Back Coat Thickness in micron 4 1

I Guard Film Thickness in micron 40 3

J Salt Spray Test Humidity Test 750 hrs 1000 hrs

Superior Stainless Steel Construction

Cold room panels made with stainless steel provide excellent resistance to corrosion and wear, making them ideal for rigorous industrial requirements. Their silver sheen ensures an aesthetic, hygienic, and easy-to-clean surface, which is crucial for industries where cleanliness and durability are top priorities.

Versatile Industrial Application

Designed for various industrial uses, these cold room panels facilitate efficient temperature management in sectors like food processing, pharmaceuticals, and logistics. The panels' compatibility with voltage ranges from 220 to 440 volts allows broad deployment in different facility infrastructures.

Comprehensive End-to-End Services

Acting as a distributor, manufacturer, exporter, supplier, and service provider, we offer end-to-end solutions. Our experts assist in everything from selection and customization to installation and maintenance, ensuring your investment delivers long-term operational efficiency.

FAQ's of Cold Room Panel:

Q: How are stainless steel cold room panels installed in industrial facilities?

A: Stainless steel cold room panels are assembled on-site using precision interlocking systems, ensuring an airtight structure. Installation is supported by experienced technicians who manage panel alignment, secure proper sealing, and integrate voltage connections for optimal performance.Q: What are the key benefits of using stainless steel cold room panels?

A: Stainless steel cold room panels deliver exceptional durability, corrosion resistance, and hygienic surfaces. They provide superior thermal insulation, energy efficiency, and require minimal maintenance, making them advantageous for industries with high sanitation standards and temperature control needs.Q: When should an industrial facility consider upgrading to these cold room panels?

A: An industrial facility should upgrade to stainless steel cold room panels when improved insulation, higher durability, compliance with hygiene regulations, or enhanced energy efficiency is required. Upgrades are also recommended during expansion or retrofitting projects.Q: Where in India can your company supply and service cold room panels?

A: We offer nationwide supply and support for stainless steel cold room panels across India. Our vast distribution network ensures prompt delivery and comprehensive service in both metropolitan and remote industrial areas.Q: What is the typical process for ordering and receiving these panels?

A: Clients begin by consulting with our technical team to determine specifications. After finalizing the order, panels are manufactured, quality-checked, and delivered to the client's site. Installation and after-sales support are provided as part of our full-service commitment.Q: How do these panels support voltage requirements from 220 to 440 volts?

A: These cold room panels are designed with electrical compatibility in mind, accommodating systems that operate within 220-440 volt ranges. This flexibility ensures seamless integration with standard industrial electrical infrastructures.Q: What makes your company a reliable partner as a manufacturer and service provider?

A: Our company stands out due to its extensive industry experience, stringent quality controls, and commitment to customer satisfaction. We offer tailored solutions, on-time delivery, technical expertise, and comprehensive after-sales service, ensuring lasting support for every client.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Rooms and Storage Category

Cold Room Doors

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : PUF Insulation

Type : Hinged Door / Sliding Door

Layer : GIPP

Voltage : 220 Volt (v)

Ice Cream Cold Room

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Puf Panel

Type : Other, Modular Cold Room

Layer : Double Layer

Voltage : 220V / 380V Volt (v)

Cold Room Sliding Door

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Type : PUF Insulated

Layer : Double

Voltage : 220440 Volt (v)

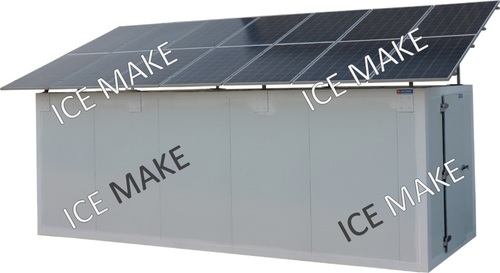

Solar Cold Room

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : GIPP

Type : Under Counter Refrigerator and Pantry Freeze

Voltage : 220440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free