Cold Room

Price 1000000 INR/ Unit

Cold Room Specification

- Material

- PU Panel (Polyurethane Panel)

- Type

- Modular Cold Room

- Style

- Double-Temperature

- Refrigerant

- R404A

- Climate Type

- T1, T2, T3

- Layer

- Single

- Insulation Thickness

- 60 mm

- Shelf Type

- Stainless Steel (Optional)

- Surface Finish

- Pre-Painted Galvanized Iron

- Floor Type

- Anti-Skid

- Compressor Brand

- Emerson Copeland

- Interior Light

- LED

- Cooling System

- Air Cooled

- Door Type

- Swing Door

Cold Room Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About Cold Room

We are a leading name in the industry, engaged in offering a classic range of Cold Rooms to our clients. This product range is manufactured using premium quality range of material taken from our industry's reliable vendors. This product range is available at market competitive price.

Range of Cold Rooms:

- PUF Panel Thickness (mm): 60,80,100,125 & 150

- Temperature: +15oC to -40oC

- Panel Surface Material: GIPP or SS 304 (2B & mate finish)

- Sheet Thickness: 0.5 to 0.6 mm

- Floor Insulation: Kota Panel, PUF Slab with tar felt sheet, Aluminium Chequered Plate, FRP Cladding

- Size: Min. 6" X 6" X 8" & max. width and length as per your requirement and height up to 39 feet(Single Panel)

- Type of Cold Rooms:Single Chamber Cold Room Multi Chamber Cold RoomNote: Above mentioned price is inclusive of GST and exclusive of Transportation, Civil Work and as per our standard model as mention below:

- Cold Room size :93" X 93" X 97.22" (405 CFT) Com pressure

- Make: Emerson CR-22

- Flooring: PUF Slab (Kotastone will be in customer scope)

- Temperature Range: +2oC to +8oC

FAQs of Cold Room:

Q: How does the 60 mm PU panel insulation benefit cold room performance?

A: The 60 mm polyurethane (PU) panel insulation ensures excellent thermal retention, reducing energy consumption and maintaining set temperatures efficiently. This insulation minimizes temperature fluctuations and prevents energy loss, making the cold room cost-effective and reliable for different storage needs.Q: What is the purpose of the double-temperature design in this cold room?

A: The double-temperature design allows users to store products requiring different temperature ranges within the same cold room, from -20C for frozen goods to +10C for chilled items. This enhances flexibility for businesses that handle both frozen and chilled inventory simultaneously.Q: When should the stainless steel shelving option be considered?

A: Stainless steel shelving should be considered when you require organized and hygienic storage, especially for food or pharmaceutical products. These shelves are durable, easy to clean, and resistant to corrosion, making them ideal for environments demanding strict hygiene standards.Q: Where is this modular cold room suitable for installation?

A: This cold room is suitable for installation in food processing plants, warehouses, pharmaceutical facilities, hotels, and supermarkets. Its robust and modular construction allows easy customization for various spaces, and it can be set up both indoors and outdoors depending on operational requirements.Q: What is the installation process for the cold room?

A: Installation involves assembling the modular PU panels, fitting the swing door, connecting the air-cooled refrigeration system with the Emerson Copeland compressor, and installing the floor and optional stainless steel shelves. Professional service and support are available for setup and commissioning across India.Q: How do users benefit from the anti-skid floor type?

A: The anti-skid floor enhances safety by providing increased traction, reducing the risk of slips and falls while handling goods inside the cold room. This is particularly important in environments where floors may become damp or icy, ensuring a safer workspace for staff.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Rooms and Storage Category

Ice Cream Cold Room

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Puf Panel

Type : Other, Modular Cold Room

Style : SingleTemperature

Climate Type : Tropical / Subtropical

Cold Room Refrigeration Unit

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Copper

Type : Cold Room

Style : SingleTemperature

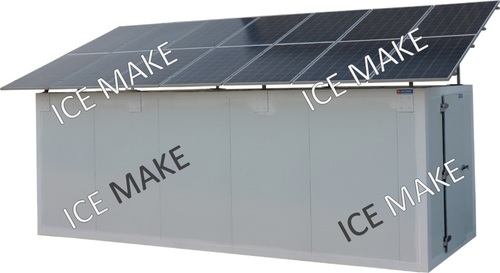

Solar Cold Room

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : GIPP

Type : Under Counter Refrigerator and Pantry Freeze

Flush Type Big Door

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel / CRCA Sheet

Type : Other, Flush Type Big Door

Style : Other, Single Door

Climate Type : Tropical / Moderate

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS