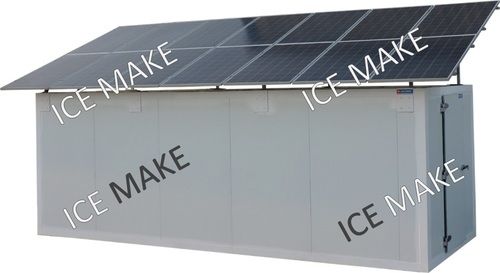

Cold Room

1000000 INR/Unit

Product Details:

X

Cold Room Price And Quantity

- 30000.00 - 8000000.00 INR/Unit

- 1000000 INR/Unit

- 1 Unit

Cold Room Trade Information

- 10 Unit Per Month

- 1 Months

- All India

Product Description

We are a leading name in the industry, engaged in offering a classic range of Cold Rooms to our clients. This product range is manufactured using premium quality range of material taken from our industry's reliable vendors. This product range is available at market competitive price.

Range of Cold Rooms:

- PUF Panel Thickness (mm): 60,80,100,125 & 150

- Temperature: +15oC to -40oC

- Panel Surface Material: GIPP or SS 304 (2B & mate finish)

- Sheet Thickness: 0.5 to 0.6 mm

- Floor Insulation: Kota Panel, PUF Slab with tar felt sheet, Aluminium Chequered Plate, FRP Cladding

- Size: Min. 6" X 6" X 8" & max. width and length as per your requirement and height up to 39 feet(Single Panel)

- Type of Cold Rooms:Single Chamber Cold Room Multi Chamber Cold RoomNote: Above mentioned price is inclusive of GST and exclusive of Transportation, Civil Work and as per our standard model as mention below:

- Cold Room size :93" X 93" X 97.22" (405 CFT) Com pressure

- Make: Emerson CR-22

- Flooring: PUF Slab (Kotastone will be in customer scope)

- Temperature Range: +2oC to +8oC

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email